Back in 1979, Paul Miller started a small, family-owned welding shop in Nappanee, Indiana, not knowing how that choice would shape his family’s future and create a business that would not only endure and grow, but also continue to embody his own personal values.

The founder of Paul’s Welding and Repair was guided not only by his strongly held Christian beliefs, but also an innovative spirit and creative mind, and both his beliefs and his entrepreneurial spirit would be carried through the business by his sons – Ryan, Darren and Kyle – who officially joined the company in 1996, though in truth they had always been a part of the operation.

“I was welding at six years old,” says Ryan Miller, the eldest of the brothers and now president and CEO of the company now known as PWI.

“Mom and dad started the company in two acres of land behind their house, and my brothers and I all grew up doing repair work and general fabrication jobs. I was always involved in the business, partly out of necessity when my father needed help. When I was 10 years old, I helped him to build our first big steel building, which meant I was even running a forklift.”

From those early days, with his father running the company during the day and then working with his sons on the building project after hours, it was clear that the company was in the family’s blood.

“My father never made me feel like I had to be involved, but I felt like I wanted to be part of this business and help him run it,” Miller explains.

Branching out

The business may have started out as a simple welding shop, but it was able to grow steadily into something much more diverse. With its focus on solving clients’ problems with high-quality solutions and its ability to build strong customer relationships, it would eventually become a highly regarded provider of innovative material handling solutions for the local RV industry.

That would be the platform for the small company to take on more industrial work and, by 2000, it had become a larger entity that was able to branch out into the manufacture of cranes.

“We were able to attract more industrial work in the 1990s, and we saw potential to expand our range,” Miller says. “A customer asked us to weld a beam for a monorail crane and from there we started to get more calls for work in materials handling.”

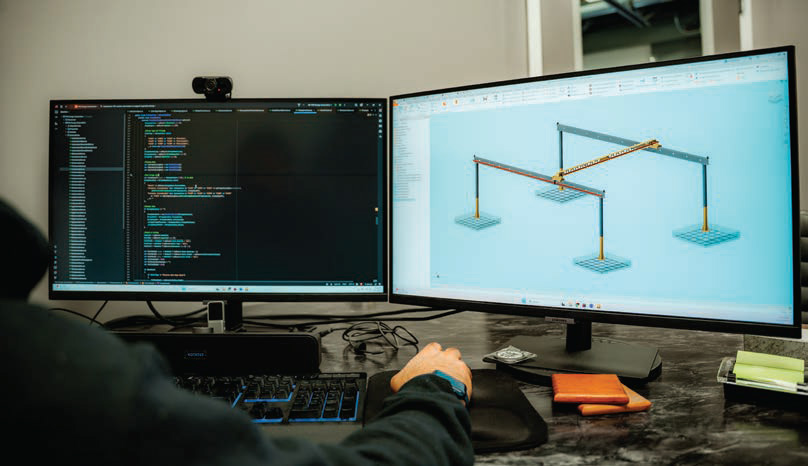

In 2015, the company took delivery of its first PCR 31 CNC plasma cutting machine and soon designed what would be the first PWI product line – the ULTRALITE workstation crane series. Two years later, the company and the family would suffer a great loss with the passing of Paul Miller after a battle with cancer, leaving Ryan and his brothers to carry on his legacy.

“Both parents died from cancer at a young age,” Miller says. “My mom died 20 years ago, and my father eight years ago, but I had already stepped into a leadership role in a new way as my dad had been stepping out to some degree due to his illness.”

Taking over from the founder of a company, and from your father, surely comes with a big burden of responsibility. Even when you have been involved from the start and picked up a welding torch for the first time at the age of six, leadership demands very different skills. In typical fashion, Miller did not shirk or shrink from the task but took a very practical approach to learning how to run the company.

“We got some outside advice to help us understand delegation for the first time,” he remarks. “I was the company’s first sales guy, and I delegated production to another leader in the business, and by doing so we doubled and then tripled the company’s business fairly quickly.”

In 2018, Miller officially stepped into the role of president and CEO, and one of his first actions was to create the company’s first executive team. Following that decision, he could use that structure as a platform on which to build a long term vision for the business.

Now, PWI is more than just a crane company. It manufactures stairways, mezzanines and many other components for the materials handling sector. The crane segment of the business is certainly the biggest part of the company, but Miller is keen not to limit the scope of his vision. Organic growth and a strong work ethic have enabled the business to adapt to changing circumstances through innovation, and that has been a key strand of its success story.

For example, in 2020 there was a slight dip in the local RV economy, so PWI was able to shift its focus to become a national supplier of overhead cranes, mezzanines and fall protection.

Those became the big three areas for which the company was known, thanks in part to a strong marketing campaign to help the business focus on what it does best. At the same time, a national sales department was established to further the company’s growth outside of its home region.

That vision culminated in its 2025 rebranding exercise, which gives the company a new identity to accurately reflect what it has become over the years and where it intends to go in the future. Focused on the key themes of innovation, relentless grit and a strong company culture, the new branding aims to bridge the traditional values its founder held dear, while aligning it with change, growth and purpose.

“Innovation, passion and grit – those values suit our family and our team really well,” Miller explains. “We are welders and manufacturers at heart, but we are focused on helping other manufacturers to fulfil their projects.”

Lessons in leadership

Having been involved in the business from such an early age, Miller had the values of the company – the same values that shaped his family – in his blood. In that sense, continuing his father’s legacy was simple. Less straightforward, however, was navigating the responsibilities that come with making strategic and operational decisions that shape the lives of a growing team of employees and, by extension, the community from which the company had emerged and in which it continues to play a prominent role.

In taking on the role of president, Miller called upon his belief in a higher power to seek guidance. He describes himself as a husband, a father, a visionary leader and a follower of Christ, and all those roles intertwined as he seeks to make his mark on the world.

“When it comes to setting a vision for the company, our faith is very important,” he says. “We serve Jesus Christ and that is a big deal. It gives us the ability to change our community, and we have an aggressive giving goal. We are always giving back to the community, and that accounts for half of the vision that we have set out. The other half is about building the culture here.”

The company currently has more than 180 team members, and Miller’s goal is to help each one become better at what they do and be valuable members of society.

“We all are focused on becoming better welders, but also better fathers and husbands and people,” he says. “We are influencing the family trees of the people who work here, so the basis of my vision is culture. Customers feel that and they experience the culture of the company when they work with us.

“I understand that not everyone here shares my faith, and that is okay, but it is all about integrity and honesty – that is who we are.”

On a more granular level, the company’s vision is to make a big push as a manufacturer to reach out to and serve its manufacturing customers across the US. It provides everything from 500lb to 50-tonne cranes, and all are built on its own premises – it does not buy and resell materials handling systems.

“Our business model, which we pursue aggressively, is to have our own sales representatives serving our customers directly,” Ryan Miller, president and CEO. Miller explains. “We are a manufacturer that designs, builds and serves our customers.

That is the model, and it is working. Our customers get a good experience knowing the equipment is built right here in Indiana, and there is that level of control that we have. That means we can do rush lead time jobs if necessary. Fully building out our product line is our vision for growth.”

Setting that corporate vision is one of the responsibilities of the CEO, but delivering on that vision is something else entirely. It requires a different set of skills, and Miller freely admits that some did not come to him naturally. But perhaps that is the mark of a really great leader – he or she knows their limitations and is always willing to learn how to do a better job.

For Miller, that meant learning to delegate. “Not being a micromanager – that was my big lesson,” he says. “My dad was sitting with me one day in the office not long before he passed and we were looking at a project spreadsheet.

He looked at all the lines and then said that I was missing one – the line of micromanagement. He understood that was an issue for me. He helped me to understand that I am the cap on the company’s growth, so the more I grow the more the company can grow.

“I have come to understand that I don’t need to be in every meeting. I can trust sales to run sales, operations to run operations, engineering to run engineering. Sure, I get into the weeds when I’m needed, but letting that go was one of the biggest lessons I had to learn.”

Room to grow

An effective leader understands that having the top job does not mean being the best at everything. To make mistakes is human, but to learn from them is what sets a good leader apart from the crowd. It is also that understanding that enables Miller to look at people rather than just pieces of paper when deciding who to bring into the business.

“We don’t get it all right, but here we make a bigger deal of culture fit than education and training,” he says. “We like experienced people, but the number one thing at all levels is who a person is rather than the skills they might have. After all, skills can be learnt. When we fire people, which is not often, it is usually for reasons of culture than for anything else. Culture is everything here. You can’t delegate to people you don’t trust.”

As well as learning to delegate, Miller has also become better at conquering the urge to get swept up in any conflicts that arise. In every business there are situations that get heated, and it takes a good leader to understand when a gentle touch rather than hasty action is required.

“I’ve learned to de-escalate tense situations and that is a really hard thing to do,” he admits.

“You can always escalate things into monsters and overreact, but I have learnt that it is okay to sleep on it for a night. If a customer’s crane has broken down, for example, the decision you make the next morning is generally better than the one you make right away. It will most likely have more grace and clarity behind it.

“The same is true when there is a conflict between two people. That has become a strength of mine and it was once my weakness. Now, I often de-escalate because that is a big part of what I must do. I have to solve problems, which are always big by the time they come to me.”

That ability to manage people effectively goes hand in hand with helping the team to understand the role they play in the company’s broader vision.

“I’ve seen the ROI on that. If people know where they are heading everything comes together. If you are paid $1,000 an hour to dig a hole in the ground and fill it in, you would not be able to do it for 10 years unless you knew why you were doing it. Part of our culture is in our giving goals, and we share those numbers with everyone, so when we fund a homeless shelter in Indiana, providing food and clothing for unfortunate people, our employees know what dollar value goes into that.”

Facing up to change

Though he is steeped in the company’s heritage and a deeply held faith that means everything to him, Miller is also open-minded about the future and how the industry in which PWI operates is undergoing change.

“I think that AI is a huge factor,” he says. “It is a cliché, but it is true. We are using tech here in some industry changing ways and automating as much of the process as we can.”

The company already has the technological capability to put customised specifications for a product into its design software and have fully engineered drawings for a new product in the customer’s inbox with a quote in as little as three minutes.

“AI is involved in that, but our software development team is using a lot of other tools and experience, so it is not true to say it is AI generated,” he explains. “The challenge will be to keep up with technology, so we have to get on the bus now. Customer experience is changing quickly, and we are constantly inventing the future.”

He firmly believes that technology will soon bring a shift towards a direct-to-consumer model in the crane industry, similar to the model employed by Tesla. That means giving customers tools to design their own cranes, cutting out the middle man. The majority of crane suppliers buy products from manufacturers and then resell them, but that will change.

“We are enabling customers’ engineers to design their own crane on our website, then manufacturers can set up delivery and install dates. We are boldly heading that way. Jeff Bezos tells people to obsess over the customers and not competitors. So we go our own way and focus on our customers’ needs. We go the second mile for them, which is why we have raving fans.”

Miller is inspired by people who are growing and scaling faster than he can. Rather than envying them, he is driven by people who are doing better than him in terms of growth and leadership, and affecting their communities in a positive way.

“I am always inspired by mentors and by people doing things that I can’t figure out how to do,” he says. “I try to meet people who are doing amazing things, and I believe it is possible for a business to be moral and ethical, as well as successful. Some large companies in our industry have lost some heart, and I want to seek some significance, while helping my industry and serving customers. That is life-changing and world-changing.”

Faith, family and fairness run deep in this business, and in a rapidly changing industry, they will no doubt hold firm.