The metals industry stands at a crossroads. Traditional material handling methods serving mills, processing, fabrication and distribution facilities are increasingly inadequate for today’s demands.

As technology has evolved, so too have the methods for handling materials. Crane operators in cabs evolved to crane operators on the ground with radio controls and are now evolving to peopleless crane operation. Autonomous automation software controls crane movements from raw material receipt to finished goods shipping.

Heavy coils, irregularly shaped ingots and razor-sharp plates require more than brute force and human precision. They demand intelligent, autonomous solutions that can operate safely and efficiently in some of the most challenging industrial environments.

In North America, there is a renewed focus on reshoring, particularly within US manufacturing. Much of this future effort relies on labour availability and expertise. As we review the statistics related to future labour needs, shortages are projected by many multiples above the need. How do we effectively meet this demand and perform in the new environment?

The answer lies not in choosing between mechanical expertise and software intelligence, but in combining them. Strategic partnerships between overhead crane manufacturers and automation software companies are creating revolutionary solutions specifically designed for the unique challenges of metals processing and distribution.

The metals challenge

The metals industry presents material handling challenges that few other sectors match. Workers routinely move products weighing several tonnes, often at temperatures exceeding 1,000°F, in environments filled with debris, electromagnetic interference and noise levels that make communication difficult. Traditional forklifts and overhead cranes, while reliable, expose human operators to significant risks, limit operational flexibility and increased operational cost.

Consider a typical steel coil weighing 25t, where a single handling error can result in catastrophic injury, not to mention significant damage to both product and equipment. Multiply this risk across hundreds of daily movements and the case for autonomous solutions becomes compelling. The metals industry doesn’t just need automation – it needs intelligent automation that can adapt to the unpredictable nature of heavy industrial environments.

The power of partnership

Overhead crane manufacturers excel at creating robust lifting systems capable of moving extraordinary loads under extreme conditions. Their decades of experience have produced bridge cranes, gantry systems and specialised hoists that can withstand the punishment of daily metals operations. However, making these systems truly autonomous requires a different expertise entirely.

Automation software companies bring artificial intelligence, machine learning algorithms, advanced navigation systems and data analytic capabilities that transform mechanical equipment into intelligent autonomous systems. When an overhead crane manufacturer partners with an automation technology and software company, the result is greater than the sum of its parts, providing systems that combine mechanical reliability with intelligent decision-making that brings exceptional value to the customer.

This synergy accelerates innovation while allowing each partner to focus on their core competencies. Overhead crane manufacturers can concentrate on engineering robust lifting solutions, while automation software partners develop the intelligence that makes these systems truly autonomous. The result is complete advanced solutions that neither company could achieve independently. This type of collaboration separates modern overhead crane manufacturers from their competitors.

Operational excellence through autonomous integration

The benefits of autonomous material handling solutions in metals operations extend far beyond simple automation. These systems operate continuously, maximising the utilisation of expensive capital equipment. Unlike human operators, autonomous systems don’t require shift changes, breaks or time off, enabling true 24/7 operations that significantly increase throughput in capital-intensive operations.

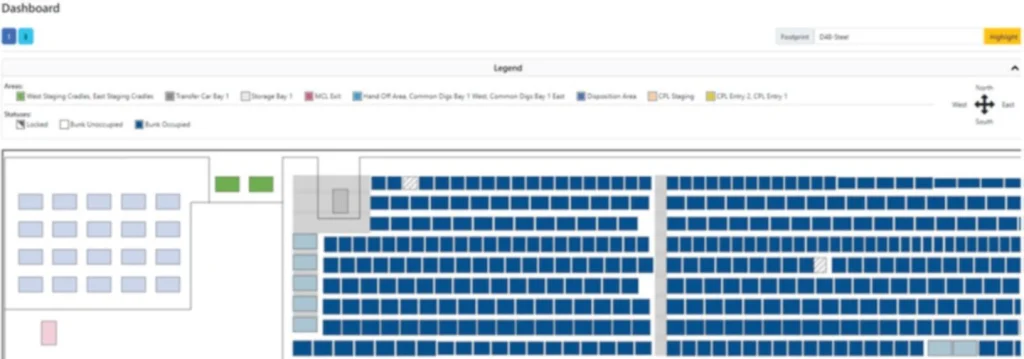

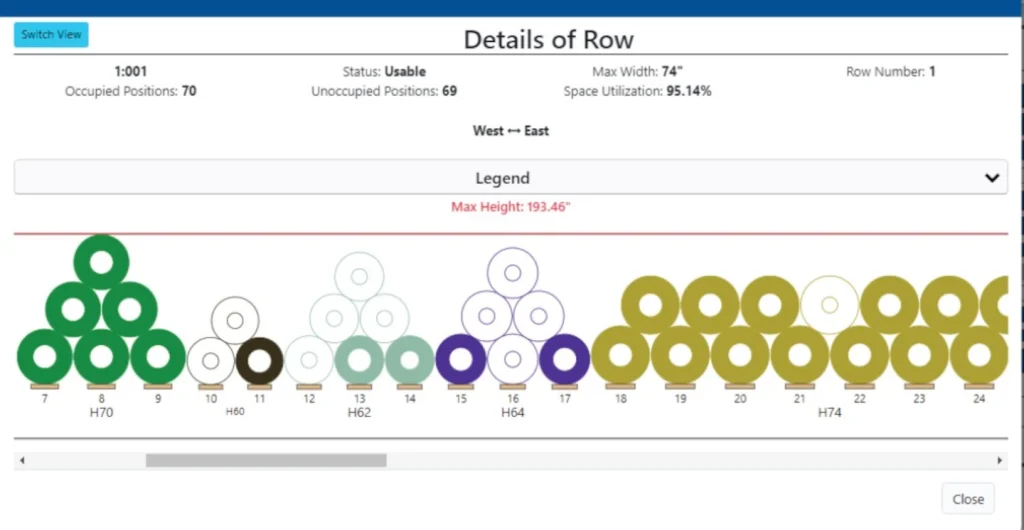

Precision becomes paramount when handling high-value products. Autonomous systems execute movements with consistent accuracy, reducing product damage that can cost thousands of dollars per incident. They optimise space utilisation through intelligent navigation and space-saving storage algorithms, enabling facilities to store more material in existing footprints while maintaining safe operating distances.

Perhaps most importantly, autonomous systems dramatically improve workplace safety. By removing human operators from direct contact with heavy, hot or sharp materials, these solutions reduce the risk of serious injuries that are faced in the metals industry. This not only protects workers but also reduces insurance costs, regulatory compliance issues and the operational disruptions that follow workplace accidents.

The hidden advantage

Modern autonomous solutions do more than move materials, they generate valuable operational intelligence. Every movement, every delay, every optimisation decision creates data that provides unprecedented visibility into facility operations. This information enables predictive maintenance strategies that prevent costly equipment failures, identifies bottlenecks that limit throughput and supports continuous improvement initiatives driving long-term digital transformation and operational excellence.

Integration capabilities allow autonomous systems to communicate seamlessly with existing Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms. This creates a connected ecosystem where material movements automatically update inventory systems, trigger production schedules, and provide real-time visibility across the entire supply chain.

The flexibility of software-driven solutions also ensures that investments remain valuable as operations evolve. Unlike fixed automation systems that require extensive modification to accommodate changes, autonomous solutions can be dynamically reconfigured as facility layouts change or production requirements shift.

Competitive advantage in a demanding market

For overhead crane manufacturers, partnering with automation software companies represents a strategic opportunity to differentiate their offerings in an increasingly competitive market. Metals industry customers aren’t just buying cranes, they’re investing in solutions that improve safety, increase efficiency and provide operational intelligence.

These partnerships deliver benefits far beyond efficient movement. Rethinking operations from start to finish allows for a new operational mindset. Reduced need for storage space, reduced operational expenses, less hazardous work environments – all these benefits contribute to an attractive return on capital spent.

Companies that can offer integrated autonomous solutions gain significant advantages in bid situations. They can demonstrate measurable returns on investment through reduced labour costs, improved safety records, increased throughput, enhanced space utilisation and operational data insights. This value proposition resonates strongly with metals industry decision-makers who must justify capital expenditures based on concrete operational improvements.

The road ahead

The convergence of overhead crane expertise and autonomous software capabilities represents more than an evolutionary step – it’s a fundamental transformation of how the metals industry approaches material movement. Companies that embrace these partnerships position themselves at the forefront of industrial innovation, while those that rely on traditional approaches risk falling behind in an increasingly competitive global market.

The question facing both overhead crane manufacturers and metals industry operators is not whether these solutions will become standard, but how quickly they can adapt to this new reality. The partnerships forming today between crane manufacturers and software companies are creating the autonomous solutions that will define the future of metals material handling.

Where safety, efficiency and precision determine success, the marriage of mechanical expertise and intelligent software isn’t just an opportunity, it’s an imperative. The future belongs to those who forge these partnerships today.