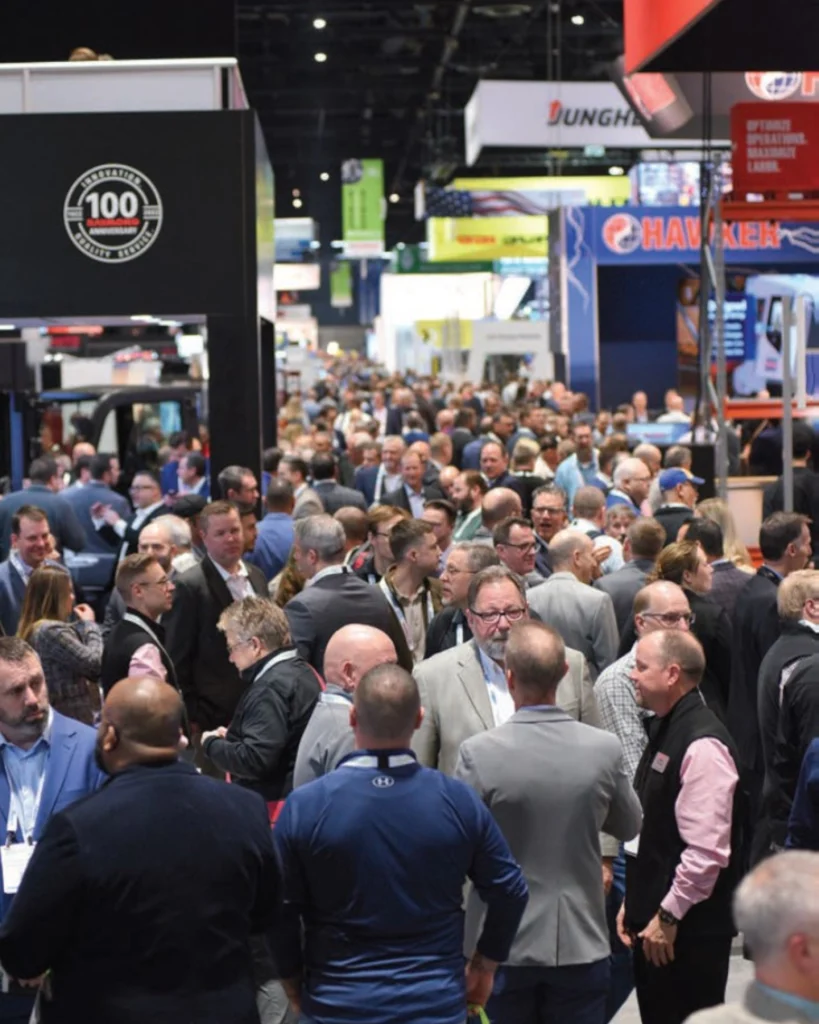

The manufacturing and supply chain community united for a record-breaking ProMat exhibition last month from 17–20 March, according to MHI. With 52,223 registrants and 1,160 exhibitors, this year’s exhibition featured 659,000 net square feet of exhibit space and hosted 215 educational sessions across three show halls at Chicago’s McCormick Place.

Marking the largest ProMat event in MHI’s history, this year saw a 3% increase in registered attendees compared to the previous show. With participants travelling from across the globe, ProMat continued to showcase cutting-edge technology and industry trends.

“ProMat brings this industry together to connect and share the best equipment and technology, the leading trends and the latest innovations. The success of ProMat 2025 is proof of the central role the supply chain plays across industries,” said John Paxton, CEO, MHI.

“No other event offers this broad range of technology and end-to-end solutions, ProMat’s unparalleled solution-sourcing, educational, and experiential offerings provide attendees with a one-stop shop for the information and connections they need to thrive in this constantly changing marketplace.”

“The energy on the show floor was very high. Attendees not only viewed the latest innovation this industry has to offer, but they also learned about them in educational sessions and connected with each other to move their companies and this powerful industry forward,” added Daniel McKinnon, Chief Exhibitions Officer at MHI.

“Attendees representing the Fortune 500, the top 100 retailers and consumer goods firms brought large teams to ProMat to source the latest technologies and to learn about the leading trends impacting supply chains. They came to ProMat with plans in hand and budgets in place to improve their operations and build resilient supply chain operations for future success.”

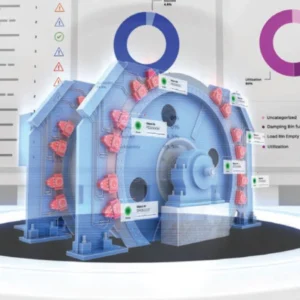

Key themes at ProMat 2025 focused on automation, robotics and AI, particularly their roles in driving end-to-end transparency and resilience. These emerging technologies were showcased alongside traditional material handling solutions, demonstrating how they work together to enable efficient and coordinated operations.

“We’re seeing a big acceleration in the adoption of these technologies in manufacturing and supply chain operations,” said Paxton. “The variety of solutions on display this year were evidence of this trend.”

Evan McKenzie, ITI/Interplay Learnings

What brought you to ProMat this year?

With ITI/Interplay Learnings’ new combined offering of facility maintenance training and ITI’s virtual material handling solutions, we wanted to see if the audience would be a good fit for our event schedule going forward. It was our first time at the show.

What new products or technologies have you seen or showcased at the event?

I think we saw some interesting use cases for virtual platforms that aim to make cumbersome tasks more automated or efficient. AI seemed to take the stage from some of the ideas I saw and interacted with.

What trends or technologies have caught your attention at this year’s show?

Sustainability, AI-powered tools and automation.

How do you feel ProMat compares to other industry trade shows you’ve attended?

For us, I think there are attendees at ProMat that are in our customer base. However, it was apparent that training seemed to be secondary to their purpose of attending the show. It was a very big show, and there weren’t a tonne of prospects that fit for us.

What has stood out the most to you at this year’s event?

I think the size of the show made it harder to stand out with a smaller booth.

What are your biggest takeaways from ProMat 2025?

There are audiences there for crane and rigging/ facilities maintenance training, but we had to drive that conversation since it wasn’t a topic in the headspace of the attendees. We will see what the ROI is for us for ProMat, but we think the show is too big and not ideal for ITI/Interplay.

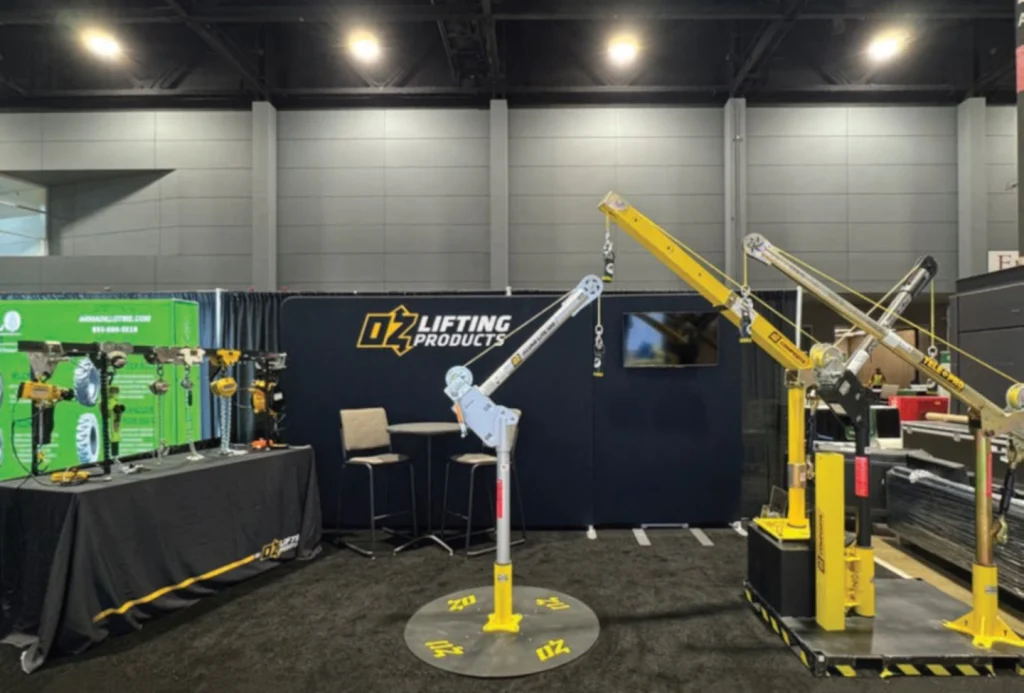

Ashley Blum, OZ Lifting Products

What brought you to ProMat this year?

I attended ProMat 2025 with OZ Lifting Products, where we were exhibiting again this year. We’ve been a consistent presence at both ProMat and MODEX over the years, and it’s always a worthwhile investment. ProMat is one of those shows that really leans into forward-thinking and innovation, which aligns closely with our values at OZ. We’re always looking for new ways to solve real-world material handling challenges, and this show gives us a chance to not only showcase what we’ve been working on, but also see where the industry is heading.

What new products or technologies have you seen or showcased at the event?

We brought several of our davit cranes to the show floor this year, including our lightweight line: the Alumi-Lite, made from lightweight aerospacegrade aluminium; the CompOZite, which uses advanced composite material, 40% lighter than traditional steel models; and the CompOZite Elite, crafted from ultra lightweight carbon fibre, making it pound-for-pound the lightest and most robust davit crane on the market.

Each of these was designed with portability and durability in mind, ideal for users who need serious lifting power without the bulk. We also showcased our Tele-Pro davit crane, which features a telescoping boom that can extend or retract under load, something that really sets it apart. Alongside the cranes, we had a selection of our hoists, beam clamps and trolleys, products that consistently deliver performance in the field.

What trends or technologies have caught your attention at this year’s show?

The advancements in robotics really stood out. I saw systems capable of recognising and sorting a variety of products on the fly, even adjusting if something was dropped out of place. A few had such fine motor control that they could manipulate small objects with near-human dexterity. Watching that level of precision in action was honestly pretty inspiring. It’s a reminder of just how quickly automation is evolving and how it might intersect with the rigging and lifting space in the near future.

How do you feel ProMat compares to other industry trade shows you’ve attended?

ProMat is unique in that it brings together such a wide range of solutions across the supply chain – from automation and software to hardware like ours. The attendees are genuinely interested in discovering new tech and talking shop, which makes for high-quality conversations. It’s less about volume and more about depth. People ask the right questions, and there’s real opportunity for collaboration.

What really sets it apart is the diversity of perspectives. You’re not just talking to people in the same lane as you, you’re meeting engineers, plant managers, buyers and tech developers from all corners of the industry. Everyone brings a different set of needs and challenges to the table. Having those kinds of meaningful conversations, where someone shares a specific lifting pain point, is incredibly valuable. It helps us see where the gaps are and inspires us to push our technology further. At OZ Lifting, we take that feedback seriously. It directly fuels how we evolve our products and expand our offerings to better serve the people actually using them.

What has stood out the most to you at this year’s event?

Beyond the tech, it’s the energy and curiosity of the attendees that really stuck with me. The conversations at our booth weren’t just “What does this do?”, they were more like, “How could I use this in my workflow?” or “Could this help us improve safety or efficiency in this specific scenario?”. That level of engagement is incredibly rewarding and helps validate the work we do back home.

What are your biggest takeaways from ProMat 2025?

One of the biggest takeaways is how important it is to stay flexible and future focused. Whether it’s lightweight materials, smarter lifting systems or adapting to trends in automation, there’s a clear shift toward innovation that’s practical and user driven. OZ Lifting is already deep into that mindset, listening to our customers, pushing for better design and making sure every product we develop meets a real-world need. ProMat reinforced that we’re on the right path and gave us even more fuel to keep pushing forward.

Ashley E Foster, GW Becker

What brought you to ProMat this year?

We came to ProMat 2025 to connect with our vendors, meet new potential customers, stay on top of industry trends, and explore innovative technologies that align with the evolving needs of our customers. It’s a valuable opportunity to see where the industry is heading and how we can continue to deliver smart, reliable lifting solutions.

What new products or technologies have you seen or showcased at the event?

We’ve seen a strong focus on automation, predictive maintenance technologies and smart systems integration. Solutions that combine overhead lifting with intelligent control systems or IoT connectivity are becoming more prevalent. We had great conversations around our custom and packaged crane systems.

What trends or technologies have caught your attention at this year’s show?

Automation and data-driven maintenance tools are certainly in the spotlight. We’re seeing more interest in how traditional equipment like overhead cranes can be enhanced with smart tech – whether it’s load tracking, safety analytics or remote diagnostics. Sustainability and energyefficient solutions also stood out as ongoing priorities for many companies.

How do you feel ProMat compares to other industry trade shows you’ve attended?

ProMat continues to be one of the most comprehensive trade shows in the material handling space. The size, diversity of exhibitors and level of innovation on display make it a top-tier event. It offers a broader perspective compared to more niche trade shows, which allows for more cross-industry learning.

What has stood out the most to you at this year’s event?

The level of collaboration and technology integration has been impressive. It’s clear that more companies are partnering across disciplines – controls, software and machinery – to deliver more complete and intelligent solutions. The energy on the floor and the quality of conversations this year have really stood out.

What are your biggest takeaways from ProMat 2025?

The industry is moving fast toward smarter, more connected systems, and customers are prioritising both uptime and long-term value. There’s also a strong emphasis on safety, sustainability and adaptability. ProMat 2025 reinforced the importance of staying agile and proactive in offering solutions that meet tomorrow’s operational challenges today.

Milestone anniversaries

During this year’s ProMat, John Paxton, MHI CEO, and Christy Dula, MHI Chief Experience Officer and Digital Technology Officer, presented commemorative plaques to recognise MHI member companies that celebrated significant milestones this year and to honour their enduring leadership and resilience.

“These companies have shown what it means to lead with purpose and evolve with the industry,” said Dula. “Their long-standing commitment to excellence and innovation continues to move our entire community forward. We’re proud to recognise their achievements and grateful for their partnership.”

MHI extended congratulations to the following members:

- Cimcorp Automation (50 years)

- OPEX Corporation (50 years)

- Muratec America (51 years)

- Alba Manufacturing (50+ years)

- Sitma USA (60 years)

- Inventus Power (65 years)

- Avery Dennison (90 years)

- Carron Net Company (91 years)

- Nashville Wire Products (91 years)

- Cotterman Company (100 years)

- Swisslog (125 years)

- Columbus McKinnon (150 years)

2025 MHI Innovation Awards

ProMat 2025 saw MHI proudly unveiled the winners of the 2025 MHI Innovation and Startup Awards, celebrating the groundbreaking solutions that are shaping the future of the material handling and supply chain industries.

A panel of industry professionals reviewed 234 submissions from ProMat 2025 attendees to select three finalists in each of the following categories: Best New Innovation, Best Innovation of an Existing Product, Best IT Innovation, and Best Innovation in Sustainability. Following a final round of vetting, winners were selected and announced on 19 March during MHI’s Industry Night.

The 2025 MHI Innovation Award winners:

- Best New Innovation – Anyware Robotics

- Best Innovation of an Existing Product – Concentric

- Best IT Innovation – Fidus Global

- Best Innovation in Sustainability – GRI

- MHI StartUp Award – Freespace Robotics