Signalpersons aren’t often used in the operation of rail-mounted overhead cranes that work in factories, mills and other industrial plants. That’s because most railmounted overhead cranes in those applications are operated from the floor using either a wired or wireless remote control.

Since the crane operator can be near the load and can move to different vantage points during a lift, he or she can usually see the load, its travel path and any obstacles quite clearly.

But sometimes the operator is located in a cab mounted up on the crane or is on the ground but unable to see the lift from start to finish because of the building’s structure or the need to handle a load behind an obstacle – for example, a piece of machinery.

It is in times like this that it is absolutely essential to have a properly trained signalperson on the job.

Signalperson directs crane operation

When a signalperson is part of a lift, he or she is almost as important as the crane operator.

Although the crane operator pulls and pushes the controls that make the crane and load move, the signal person tells the operator where to move them and at what speed. That means the signalperson is, in effect, running the crane.

OSHA considers the signalperson’s instructions so important that the agency requires a crane operator to follow them unless he doesn’t understand what he’s being asked to do.

Signaller must be qualified

Although a signalperson typically does some other job – for example, rigging – most of the time, signalling is so important that OSHA requires a person to be trained and qualified before they do it.

Because of that, Crane Institute of America (CIA) includes signalperson training as part of its rigging-training courses.

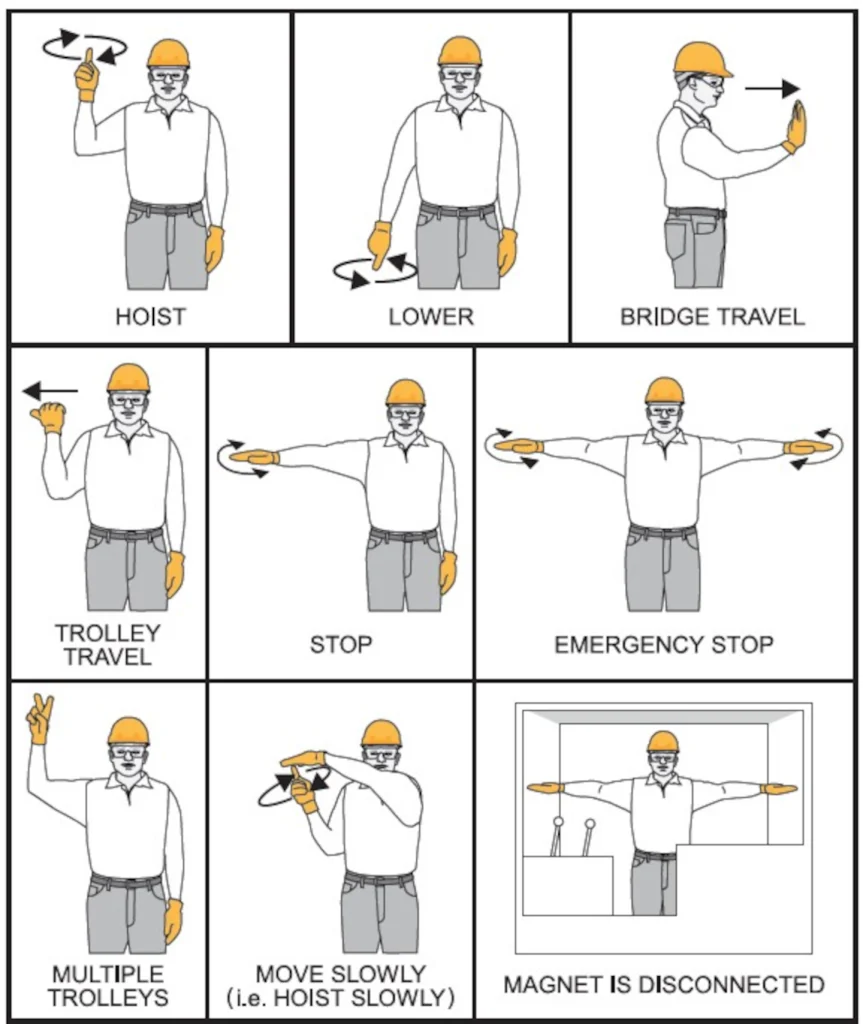

To meet OSHA’s definition of being qualified to signal, a person must thoroughly understand the basic hand/voice signals used with overhead cranes, as well as how to use them.

Beyond that, a qualified signalperson must also have a basic understanding of how an overhead crane works, its limitations and the dynamics of lifting, moving and stopping loads. That vital knowledge keeps the signalperson from directing the operator to do something beyond the crane’s capability.

In addition, a qualified signalperson must be able to identify and avoid site hazards like structural obstacles, machinery and power conductors. They must also be able to analyse the crane’s and load’s travel paths to make sure the load will not be above people and that no one will be struck by any part of the crane. OSHA holds the employer responsible for making sure a signalperson is qualified.

Training and evaluation required

To meet OSHA’s definition of “qualified”, a signalperson must learn the things mentioned above and also pass assessment by a competent evaluator, as defined in OSHA standard 1910.179.

A potential signaller can learn the necessary knowledge and skills in many ways. An employer can send them to a professional trainer like Crane Institute of America, whose courses are available both in person and now online.

An employer can have a knowledgeable person from its organisation – for example, a safety specialist – teach the aspiring signaller. The employer can even assign one of its experienced signallers to mentor the novice.

In any case, experience has proven that a combination of classroom and hands-on training is most effective.

Once trained, aspiring signallers must be assessed as qualified by a competent assessor designated by their employer. The assessment can include oral and written questions about crane operation and safety, as well as questions about any plant-specific procedures and, of course, demonstration of the standard hand signals used with overhead cranes.

It’s important to note that OSHA requires the employer to keep a record of the assessment. Only then can a new signalperson legally begin giving signals to a crane operator.

Clear communication is vital

Constant communication with the crane operator must be maintained during the operation of moving loads.

Safe and successful crane operation depends on clear, accurate communication between the signaller and the crane operator. The signals between the two may be visual, verbal, or a mix of the two.

Before beginning a lifting operation, the operator and signaller must identify each other and confirm the signals to be used and how they will be delivered.

Special signals may be used for cranes with separately operated hoists, special operations or crane attachments not covered by standard hand or voice signals.

If special signals are needed, they must not conflict with standard signals, and the signalperson and crane operator must agree on them in advance.

Directions given to the crane operator must be presented from the crane operator’s perspective. For example, ‘trolley right’ must mean move the trolley to the operator’s right.

Verbal instructions must contain these elements in this order:

- Function and direction

- Distance and/or speed

- Function stop.

Also, verbal directions must be continuous. For example: “Travel north 25ft – 15ft – 10 ft – 5ft – 2ft – travel stop.”

Before a signalperson gives the crane operator directions to do multiple functions at the same time – for example, trolleying and load lowering – the signaller should consider the lift’s complexity, the crane’s capability, the operator’s skill and the ability to communicate the needed voice signals.

Required procedures

When a signalperson is involved in a lift, he or she must:

- Be positioned where he or she can clearly see the crane operator, the travel path and where the load will be placed

- Keep non-essential people out of the work area

- Never direct the load over people

- Not give directions that would move a load if the travel path isn’t clear

- Communicate continuously with the operator. If communication is disrupted, equipment movement must be stopped until communication is restored

- Give signals that the operator can see or hear and understand. If the operator cannot understand a signal, he or she must not respond

- Use standard the standard hand signals prescribed in applicable ASME B30.2, B30.16 and B30.17 standards, unless voicecommunication equipment is used.